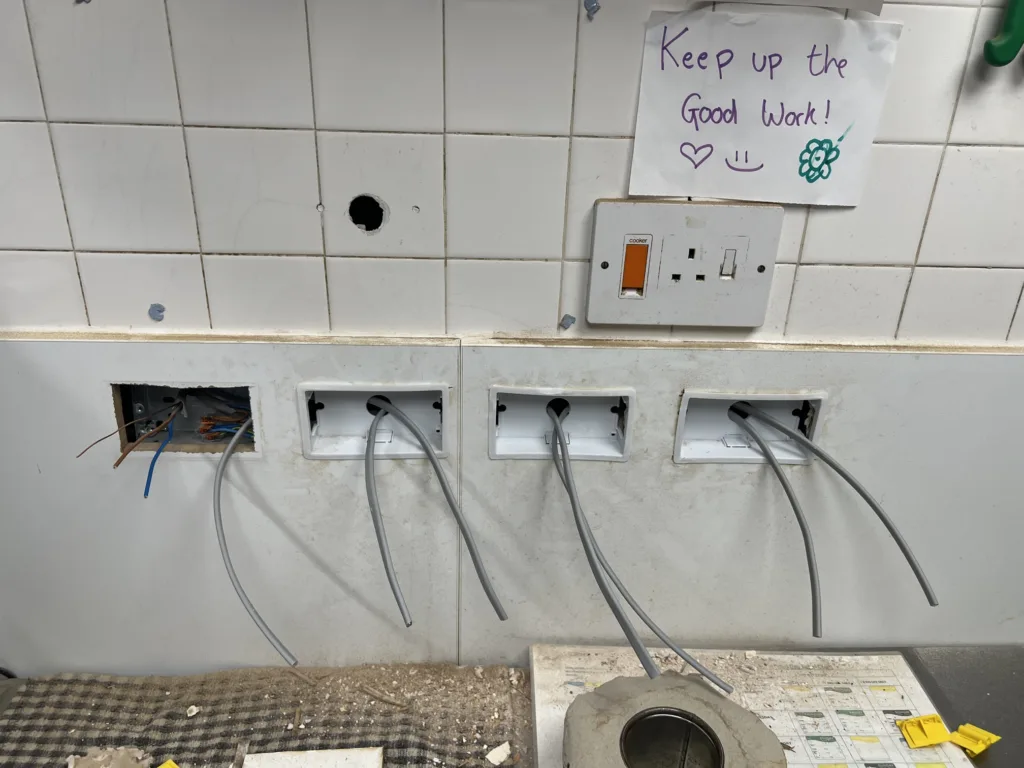

Our team installed three recessed double socket outlets at counter-top height in a Camborne commercial kitchen, improving workspace functionality and power access for food preparation equipment.

The commercial food sector presents unique electrical requirements that demand careful consideration of both functionality and safety. When a Camborne establishment contacted us about their kitchen power needs, we quickly identified that their preparation area required additional power outlets to support their expanding operations.

The client’s kitchen preparation space had limited access to power, creating inefficiencies in their daily operations. Staff were struggling with insufficient socket access, leading to workflow disruptions when preparing food. With food safety and operational efficiency as priorities, the client needed a professional solution that would integrate seamlessly into their existing kitchen setup.

After assessing the site, we recommended installing three double socket outlets at counter-top height in their preparation area. This strategic placement would allow for convenient access to power without compromising valuable workspace or creating potential hazards with trailing cables across work surfaces.

Our installation approach focused on maintaining the cleanliness and professional appearance essential in commercial food environments. We used recessed double socket outlets that would sit flush with the surrounding surfaces, preventing the accumulation of food debris and allowing for easier cleaning—a critical consideration in commercial kitchen environments where hygiene standards are paramount.

The cabling requirements demanded careful planning to ensure minimal disruption to the kitchen’s operation. We routed all wiring through 20mm PVC conduit within the adjacent store room, creating a neat installation that met all current regulations while remaining accessible for any future maintenance needs. This approach also meant that we could maintain the integrity of fire-rated walls and avoid compromising the building’s safety features.

The recessed fitting method involved careful cutting and preparation of the wall surfaces to accommodate the dryline boxes, ensuring a secure and flush installation. Our team worked methodically to minimise dust and debris, using appropriate containment measures to prevent any contamination of food preparation surfaces. All three socket positions were prepared simultaneously to streamline the installation process.

With the sockets securely mounted, we completed the wiring connections to the existing circuit, ensuring all terminations were properly executed and insulated. The trunking installation provided additional protection for cables while maintaining a professional finish that complemented the kitchen’s existing aesthetic.

Following the physical installation, comprehensive electrical testing was conducted on the circuit to verify its integrity and safety. This included insulation resistance testing, polarity checking, and earth continuity measurements—all essential components of a thorough electrical certification process. The testing confirmed that the installation met all requirements of BS 7671 (the UK wiring regulations), giving the client complete confidence in the safety and reliability of their new power outlets.

The entire project was completed efficiently within a single day, minimising disruption to the kitchen’s operations. Upon completion, the client received full electrical certification documenting the installation and testing process, providing them with the necessary paperwork for their insurance and regulatory compliance needs.

The finished installation provided the client with conveniently located power access that improved their workflow efficiency while maintaining the high standards of safety expected in commercial food environments. The recessed design of the sockets complemented the kitchen’s professional appearance while supporting easier cleaning and maintenance—factors that are particularly important in food preparation areas.

This Camborne commercial kitchen socket installation exemplifies our commitment to delivering practical electrical solutions that address specific business needs while adhering to the highest standards of safety and workmanship. The strategic placement of commercial sockets in this food preparation area has directly contributed to improved operational efficiency and workplace safety, demonstrating how thoughtful electrical installations can provide significant benefits for commercial clients.

Ready to make a difference? Explore exciting career opportunities with us!